Despite constant warnings that the end of internal combustion is near and that electric power will take over in the imminent future, there is still a substantial amount of development work on combustion engines as manufacturers make them more and more efficient. Variable valve timing is just one way that hasn’t been explored by most motorcycle companies, but now Piaggio is developing a VVT configuration specifically for small, low-cost engines.

The company’s design, revealed in a detailed patent application, is intended to change the intake timing on a single-cylinder engine with a single camshaft at the top, for use in scooters. This puts particular pressure on the design, as profit margins in this part of the market are tight, making simplicity and a reduced number of components particularly important.

At first glance, Piaggio’s SOHC VVT system looks almost identical to the design that Yamaha uses in its “VVA” (Variable Valve Actuation) engines, which are fitted to a variety of motorcycles, including the YZF-R125 and MT-125, as well as the Aerox 155 scooter. But there is a subtle difference in the design that should give the Piaggio system an important advantage.

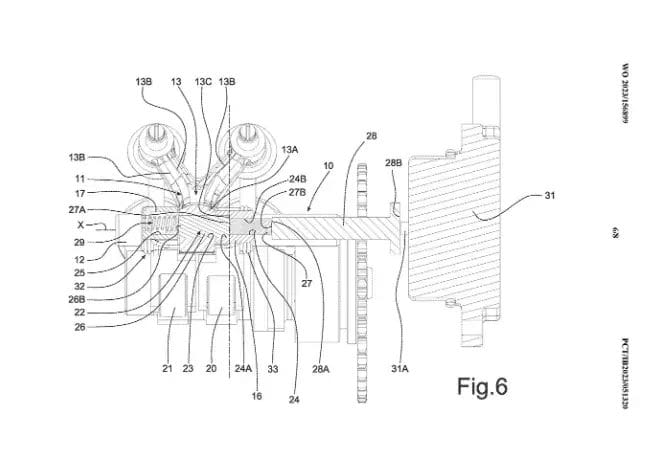

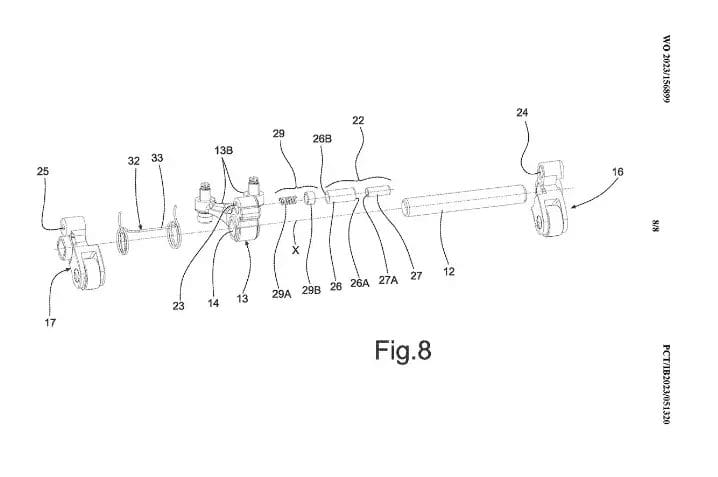

Like Yamaha’s VVA system, Piaggio’s design uses two profiles for the intake cam segments, acting on a bifurcated oscillating shaft that transmits the movement of one or other cam segment to two intake valves. Also following in Yamaha’s footsteps, the system uses a pin in an extension above the main part of the rocker arm shaft to switch on or off the part of the rocker shaft that follows the “high rotation” cam segment, with an actuator to insert the pin and a spring to switch it off when the second segment is not needed.

But this is where there is a fundamental difference that separates the capabilities of the two systems. Yamaha’s VVA has two parts to its swingarm. One is a relatively conventional swingarm that acts on the shorter-duration, lower-lift cam segment at “low revs”. It is a single piece that runs from the end of the camshaft to the end of the valve, rotating on the axis of the middle swingarm. The second part is an element of the swingarm that is driven by the high-lift, long-duration cam segment, designed to maximize power at higher revs. It is this section that can be switched on or off by the locking pin, moved by the actuator inside the cylinder head.

In contrast, the Piaggio system has three elements in its swingarm. The central part, in the shape of a Y, rotates on the axle and has an extension above to accommodate the locking pin. It is flanked by two arms that rotate on the shaft and extend towards the camshaft, one for the “high speed” segment and the other for the “low speed” segment. The locking pin, controlled by an actuator very similar to Yamaha’s, slides back and forth on the extension above the shaft to connect one or other of the cam segments to the Y-shaped arm that operates the valves.

In operation, this gives the Piaggio system a distinct advantage, because it means that the valve timing can be changed, as well as the lift and duration. The Yamaha system can only switch between a low-lift, short-duration sector and a high-lift, long-duration sector. This change moves the other away from the softer cam segment, but does not disconnect it from the valves. In contrast, Piaggio’s design completely disconnects the low-revving part of the oscillating shaft from the high-revving part when it is actuated, so as well as having a different profile, the high-revving cam segment can have a different timing (the timing is retarded to keep the intake open later in the cycle at high revs).

The patent illustrates the system in what appears to be the engine of the Vespa GTS 300, which is also used in other models, including the Piaggio MP3.