Variable valve timing and lift systems had a slow start on motorcycles, but their number has grown exponentially over the last two years as brands such as BMW and, more recently, KTM have embraced the technology – showing that, despite rumors about the demise of the internal combustion engine, it continues to be improved year after year. Now, Suzuki looks set to join the fray with a new low-displacement VVT twin-cylinder engine, following the publication of patent applications showing its design.

Suzuki already has experience of variable valve timing on motorcycles. The company’s latest GSX-R1000 design, introduced in 2017, uses an unusual all-mechanical cam phasing system that relies on centrifugal force to change valve timing as engine revs increase. It’s a design that the company created to get around MotoGP rules that specifically prohibit electronic and hydraulic VVT and, having proved its worth on the track, it has been adapted for the sports version for riding on public roads. We’ve also seen patents that suggest Suzuki is working on a more conventional hydraulic cam phasing system for future versions of the Hayabusa, using the same kind of technology that has already been adopted by companies like Ducati.

But these VVT cam phasing systems only change the valve timing, moving it a few degrees forward or backward to increase performance or reduce emissions. The most advanced VVT configurations also change the valve lift (how wide the valve opens) and duration (how long it stays open), switching between two completely different cam lobe profiles. We’ve seen this type of technology adopted at the top end of the market with cam-shift systems such as BMW’s and the one that KTM has now added to the new 1390 Super Duke, which slides the intake camshaft sideways to change the lobe that acts on the intake valves. Further down the market, we’ve also seen variable timing and lift systems appear, notably Yamaha’s VVA system, used on the latest MT-125 and YZF-R125. These low-end systems, built for SOHC engines, use two-part oscillators to actuate the intake valves, and it’s this design that Suzuki is now working on for a new low-displacement twin-cylinder engine.

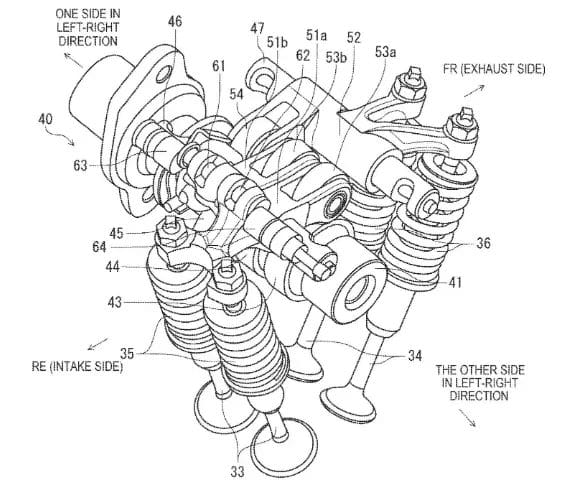

The basic principles of the idea are already well proven in production. The single camshaft has three lobes for each cylinder: an exhaust lobe and two different intake lobes, one with a high-lift, long-duration profile and the other with a low-lift, short-duration version. The cam lobes act on the valves via rocker arms and the VVT system is based on a two-part intake valve rocker arm that allows the valves to be opened by either of the intake cam lobes. A metal pin is inserted using oil pressure to lock the two halves of the intake valve rocker when the most extreme high-lift profile is required, and retracts to unlock them and return to the smoother cam profile. Suzuki’s new patent addresses the details of the system and the way the pin is driven, with the aim of reducing wear and making it more compact than other models, but it is essentially the same configuration that Yamaha’s VVA engines use.

Source:https://www.cycleworld.com/motorcycle-news/suzuki-new-vvt-engine/